The National Fund for Scientific Research (NFSR) was founded on 2 June 1928 after a call by king Albert I of Belgium for more resources for scientific research.

Among the earliest NFSR projects funded were the stratosphere flights of professor Auguste Piccard. The FNRS Stratospheric balloon that set the world altitude record in 1931. The FNRS also funded the FNRS-2, which was the first ever bathyscaphe deep sea submersible.

Auguste Piccard named his stratosphere balloon and early experimental Bathyscaphes FNRS in appreciation of the financial and scientific help he got from the institution.

Stratosphere Gandola FNRS with Auguste Piccard

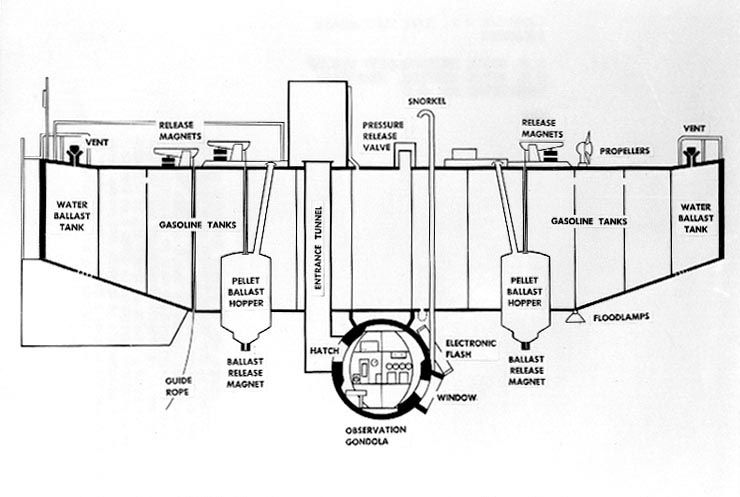

Bathyscaphe FSNR 2

Bathyscaphe FSNR 2

B

Auguste had started the Bathyscaphe project before the WW2 and restarted it again in 1948, calling the Bathyscaphe FNRS 2.

The cabin habitate and float chamber were non towable unlike the later models, the pressure cabin was made of cast steel in two hemispheres and machined to ensure the seatings of two hemispheres matched perfectly, with a autoclave outer rubberised joint. and an outer steel holding pressure band . Using conical plexiglass for the two viewing portholes which proved to be excellent material under high external water pressure.

The upper float were 6 upright petrol chambers surrounded by a 1mm thin walled steel outer sheet casing. The float arrangement was really a financial compromise and overall wasn’t that satisfactory. The upright floats were sequestrated aluminium V2 fuel rocket containers captured during allied advance through Belgium.

On completion of the Bathyscaphe it was loaded aboard a steam ship the Scaldis for Dakar French Senegal in West Africa for underwater sea trials near the Cape Verde islands.

When Scaldis arrived at Dakar the French Naval Vessel came out to meet them the Elie -Monnier on board was Captain Cousteau. He with co inventor developed the Gagnan – Cousteau Aqua -Lung (open circuit demand valve) which revolutionised SCUBA ( Self Contained Underwater Breathing Apparatus) diving for military divers then later for civilian sports recreational diving.

Two more French navy vessels were available to assist the dive trials and the local French navy Admiral offered engineering assistance and generous help and support from the French Navy.

The flotilla went to Bao Vista for first dive trials the Elie Monnier used its echo sounder to select a reasonable flatish dive site.

The first descent was made to 25 metres to check the buoyancy after filling the Bathyscaphe floation tanks with 7000 gallons of petrol and check out unballasting these intial test were made uncrewed.

Bathyscaphe automatically jettisoning ballast by turning off the electomagnetic coils to release the iron shot at a specified depth. The trial dive was to check for leaks around plexiglas potholes and various electrical and pressure gauge penetrations into the breathing capsule.

Next dive was a manned dive with Professor Piccard and Professor Monod. Auguste Piccard remembered the amazing blue of the water and the blue light that penetrated into the cabin, Auguste mind wondered off thinking that he was Captain Nemo of the Nautilus.

No sooner had they left the surface when there was jolt when they hit bottom. After about 15 minutes they decide to surface by simply pressing an electric button to release the magnetic current to release the shot ballast for the ascent to the surface. Piccard was pleased with the intial trials and the Elie Monnier picked out a new dive site off Fogo.

The dive trials weren’t all plain sailing with number mishaps but on the 3rd November 1948 they sucessfully completed an unmanned dive to 4,500 feet 1,400 metres. Unfortunately that put an end to the trials but overall the trials had proved the concept of a free diving Bathyscaphe.

Piccard realised they needed to develop and modify the overall float design concept and more financial backing was required, however without the overall success of FNRS 2 concept FNRS 3 and Trieste barthscaphes would never of been born.

Discussion with French navy about the difficulties with FNRS 2 the Barthyscaphe needed to be modified so it could be towed to a dive site as opposed to being lifted on and off a support ship by a crane.

A larger floatation chamber and working platform with an access conning tower was required so the crew could enter the submissable pressure capsule below water.

The Fonds National signed a contract with their French national scientific counterpart. Professor Piccard was to become a technical advisor with French Navies diving facility at Toulon. The French Navy would utilise the pressure capsule of the FNRS 2 and transform the above floatation chamber for towability and crew access.

Unfortunately Professor Piccard quickly realised that it was difficult working as a technical advisor with the French navy, as he had no rank or real authority, which made advising difficult and he probably got side lined by the French Navy on decision making processes. I can understand how he felt, the project was drifting away from him, after all it was his technical concept and he’d already proved the technical merits at Cape Verde.

Bathyscaphe Trieste

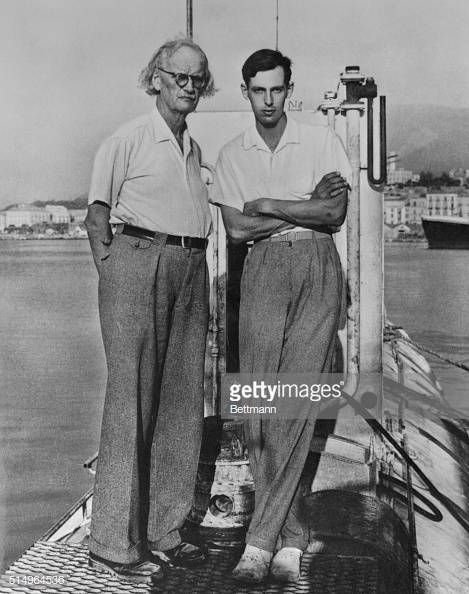

The bathyscaphe diving Pioneers Auguste & Jacques Piccard stood on the Trieste.

In the spring of 1952 both Auguste and Jacques accepted a proposal from the city of Trieste to build a new Bathyscaphe hence the new name of the Trieste. The Swiss government assisted in financial funding and Italian industry gave assistance and technical support. Basic overall design was similar to FNRS 2/3 but modifications in the float size and a conning tower shaft to the observation capsule below the floatation chamber.

Trieste at that time was a militarisied Free port independent province. Nearby was the industrial shipbuilding facility of Cantieri Riuniti Dell Adriatico shipyard who were to carry out the fabrication and construction of the new larger Bathyscaphe floation chamber.

A new pressurised habitat cabin was to be made at Terni north of Rome at Marmora. This time the high pressuried cabin sphere was made of forged steel instead cast steel. Terni had one of the largest forging facilities in the world. This would signiificantly reduce the amount of machining required with cast steel sphere and increase the tensile strength of the dive habitat sphere..

Example of small drop forging operation.

https://youtu.be/mpE9KXJPU2YOn completion of bathyscaphe Trieste the Adriatic was too shallow for deep diving trials so the bathyscaphe floatation chamber had to transported to Naples by truck from Trieste. The Pressure cabin sphere from Terni north of Rome.

The Italian navy offered the dockyard facility at Castellammare di Strabia near Naples. At Catellammare the overall bathscaphe assembly instrumentation was completed. The assembly construction which took about 8 months to complete.

First test dives were conducted south of the isle of Capri having been towed by naval tug boat to the dive site.

Once the prelminary dives had been completed a dive was planned to 550 fathoms or 3,500 feet for 26 th August 1953. They had a naval corvette the Fenice to maintain an exclusion zone for resurfacing after the dive. Lots of small incidents seem to constantly occur but weren’t insumountable for them to cancel the dive. They touched bottom at 594 fathoms.

Draeger rebreathing apparatus inside the pressurised cabin had been fitted to maintain breathiing air at one atmosphere. I’m familiar with draeger diving rebreathers having used a semiclosed drager dolphin system in the early 2000’s when I was undertaking tecnhnical training advanced Nitrox course in Egypt.

The diving habitate had to maintain breathing air throughout the duration of the dives. This consisted of HP pressure cylinders to top up oxygen contain of the air. Atmospheric air is 79 % Nitrogen and 21 % Oxygen and other trace elements.

Every time you breath out you exhale Co2 (Carbon Dioxide) and water vapour plus air. The body requires oxygen to reoxygenate the blood via the lungs. To remove the water vapour and CO2 it has to be scrubbed through sodium hydroxide to remove the CO2. The air in the habitate capsule had to be monitored for oxygen, CO2 and water vapour levels.

Shortly afterwards the Bathyscaphe was towed out to the Isle Di Ponza for further deeper dives to achieve the deepest dive so far of 1,700 fathoms 10,200 feet.

Drager Dolphin Semiclosed Rebreather.

https://youtu.be/Vo222COJ3Z0After many succesful dives in the Mediterranean the US Navy approached Auguste Piccard and a Dr Dietz of the Naval research met with Auguste in London to dicuss the project that the US navy had in mind for the Bathyscarpe Tieste. Project came to be called ” Nekton ”

The americans wanted to acquire the submersible for the exploration of the deepest point in the worlds ocean at the Challenger deep at the end of the Marianas trench. The US government purchased the Bathyscaphe Trieste and had a new pressurised capsule sphere made Krupp Iron Works of Germany. The Trieste was transported to San Diego for complete refubishment with the float chamber re-extended by 15 metres.

Various test dives were under taken at San Diego before the Freighter Santa Maria took her out to Guam the US naval base at Apra harbour. Guam is part of the US overseas territories in the Pacific, ideally base for the deep dive operation at Challenger deep. Futher dives were completed before Trieste was towed out to the final dive site off the Mariana Trench

Pathe News Reel of the Bathyscaphe diving off Capri

https://youtu.be/_O-8ia2POIANext blog post to continue the final part of the deepest dive of the Bathyscaphe Trieste.