When I left the army in 1979 I went to the Under Water Training Centre at Fort William on the shores of Loch Linnie. At that time the government sponsored individuals to train as commercial air divers for underwater construction working.

The Royal Engineers had a dive section in each troop for underwater construction work, surprisingly enough I didn’t train as a military diver.

About 6 weeks into the air diver course we spent a week using the old fashion standard diving equipment. Bronze helmet, canvas suit, breast plates and leadlined boots. The air was fed from the surface using high pressure air cylinders. In bygone days they pumped air to the diver using a hand cranked air pump.

Siebe Gorman & Co. Ltd. was a British company that developed diving equipment and breathing equipment and worked on commercial diving and marine salvage projects. It has its orgins from 1819 when founded Augustus Siebe founded Siebe and Co. The company advertised itself as ‘Submarine Engineers’ and traded at 5 Denmark Street, Soho.

During the Standard Diver training week at the Underwater Training Centre we spent most of the time learning to kit up. The canvas suit was put on first followed by a bronze neck piece that fitted the top of the open canvas suit which had to be screwed down to make it water tight seal.

heavy lead lined boots were fitted and then heavy lead breast ballast plates hung over the top of the suit. leather belt with dive knife and finally the bronze helmet. A rope was attached for signalling the surface by pulls and bells to indicate what you were doing on the bottom to the surface. Ready to leave surface when youd reach bottom,etc. The dive tender would reciprocate what rope signal you’d given him.

In fact all us trainee air divers really enjoyed the standard dive equipment training week,why? You had amazing purchase to work meaning even when using a jack hammer you couldn’t be pushed away from the work equipment you were using because with lead boots and lead breast weight you were held virtually solid on the bottom. This is the disadvantage of normal scuba gear or even modern surface demand equipment you’re purchase power is a problem due to your buoyancy.

To come up to the surface you had small valve at the back of the helmet that you pressed to “spindle up” stopped air coming out of the suit or back of the helmet. You had to fill enough air in the suit to make yourself bouyant to come up to the surface. Not to over inflate because you could come up too quickly and over inflate and shoot up to the surface like Michelin Man. Which would be dangerous on a deeper dive. Air was fed from the surface, in old times by a hand cranked air compressor.

https://youtu.be/CsCXlbURBU4

The hero of this story is a commercial air diver called William Walker. Who’s William Walker you might ask? Bill more or less with own bare hands prevented Winchester Cathedral from collasping due to its foundations sinking and subsiding into the boggy Catherdral ground. Bill worked as an air diver at Portsmouth dockyard for Siebe Gorman. The civil engineer tasked to try rectify the problem at Winchester Cathedral had tried more conventional ways of shoring up the catheral foundations but to no avail due to the rising ground water as the catheral stand close by to the river Itchin.

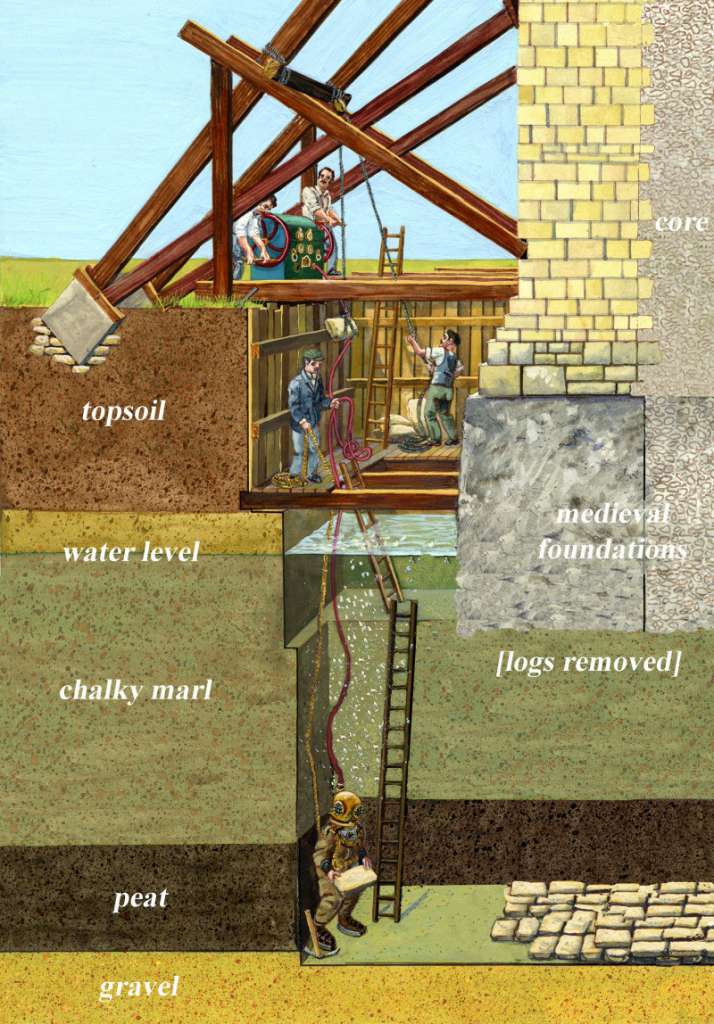

Winchester Cathedral delicately stands on peaty soil with a high water table underneath it. In the early 1900s, huge cracks began to appear in the massive walls of the cathedral and chunks of stone occasionally fell to the ground. It was only a matter of time before it became clear that the building was in danger of imminent collapse. The architect Thomas Jackson was called upon to remedy the situation once and for all as the condition was getting dire by the day. After much consultation, Jackson decided to dig narrow trenches underneath the walls of the building and fill them with concrete. These would need to reach 4 meters (13 feet) below the water table to be effective.1 The plan to dig pits through which the foundations of the cathedral wall would be shored up almost failed before it even started—water flooded the trenches so rapidly as the workmen dug that even a steam pump brought to the site could give no respite.

When the cathedral collapse almost seemed inevitable and as gloom covered the rescue project, a ray of hope came when the project’s engineer, Francis Fox, had a brilliant idea to call in a diver to help out if the water couldn’t be held back.This was how the destiny of the cathedral and that of William Walker crossed paths and was sealed forever. Walker was an experienced diver working at Portsmouth dockyard and a native of Newington, Surrey.

From 1906, using his bare hands to feel his way through the blackish muddy waters, William Walker laboured below the cathedral in total darkness for six hours every day at depths up to 6 meters (20 ft) for about six years, shoring up the foundation with bags of concrete prepared by the other workers. At the end of his work on the cathedral, Walker had packed the foundations with an estimated 25,000 bags of concrete, 115,000 concrete blocks, and 900,000 bricks.Not two, not five, but twenty-five thousand bags of concrete by any account, this is an unprecedented scale of construction work done by a single man. Only after this could the waters be pumped out and huge buttresses added to the south side of the cathedral, and the building was safe at last.

Bill Spent 6 hours a day immersed in cold black zero visibility water everything was done by feel, physically placing thousands of sandbags under Cathedrals foundations. At the end of each weeks work he’d cycle back and forth to London where his family lived.

I mean what a guy? Such a single minded devotion to task at hand what an individual. He worked with a civil engineering support staff but when underwater he was totally alone. He started work in 1906 and finished the job 1911. But unfortunately he had a sad ending to his life dying in the 1918 flu epidemic, which went on to killed thousands people. In fact more people died in flu epidemic then the total deaths of the first world war!

Under Water Training Centre Fort William

https://youtu.be/y2V3_ZSzxwwSpecial note: civil and mechanical engineering construction work is dangerous which I can vouch for myself after having a serious accident back 2012 in a power station in North Wales. I had a serious fall from height inside a large steam boiler fracturing my neck in the process. Underwater construction work is even more so. When things go wrong be it on the surface or underwater those accidents can be life threatening. Every large contract I was on as high pressure welder someone seem to get hurt, some times with fatal consequences.

Human nature really, that’s how most accidents happen, its unintended consequence. Someone has cut corners, or got complacent in some way. Usually we humans are the weak link in accident causation.